Gingerlines Modular Fabrication and assembly L.L.C

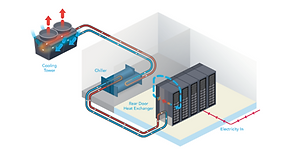

End-to-End Liquid Cooling Infrastructure for Data Centers

Liquid Core™ is a proprietary liquid cooling infrastructure system engineered and delivered by Gingerlines Modular Fabrication & Assembly L.L.C.

The system covers the full lifecycle of liquid cooling pipelines — from early engineering and design through fabrication, testing, and final technical handover.

What We

Offer

01

Engineering Modelling & System Design:

-

Intelligent 3D modelling of liquid cooling pipeline networks.

-

Routing optimization to reduce joints and interfaces.

-

Design coordination with CDUs, manifolds, and equipment.

-

Engineering decisions finalized before fabrication.

03

Controlled Spool Fabrication:

-

Workshop-based stainless steel spool fabrication.

-

Material segregation and dimensional control.

-

Precision forming and machining operations.

-

Consistent fabrication quality across all spools.

05

Testing & Verification:

-

Pressure testing of fabricated spools and assemblies.

-

Leak integrity verification as specified.

-

Visual inspection of treated weld areas.

-

Confirmation of fabrication readiness prior to delivery.

02

Weld Reduction & Advanced Pipe Forming:

-

Engineering-driven weld minimization strategy.

-

Formed tees, reducers, integral flanges, and spool-integrated bends.

-

Elimination of unnecessary fittings and segmented components.

-

Leak risk reduction through design optimization.

04

Precision Orbital Welding & Post-Weld Treatment:

-

Orbital welding for stainless steel liquid cooling systems.

-

Controlled weld geometry and verified internal root condition.

-

External and internal pickling & passivation.

-

Restored corrosion resistance and surface cleanliness.

06

Documentation & Technical Handover:

-

Fabrication, welding, and treatment records.

-

Inspection and test reports.

-

Full technical traceability.

-

Structured handover for client and consultant review.